Introduction

Threshing is the detachment of grain from the plant by striking or rubbing or squeezing or a combination. These phenomena separately or in combination complete the threshing process. Various designs of threshing mechanisms have been developed to thresh cereals crops and to obtain maximum threshing efficiency with reasonably less grain damage. The physico-mechanical properties of the crop like the type of ear head and bond strength of the grain in the panicle are the main characteristics which determine the selection of proper threshing mechanism for getting maximum results. The threshing efficiency is more in the rasp bar cylinder compared to wire loop cylinder. Sarvar and Khan (1987) stated that the various threshing mechanism, rasp bar mechanism will give best out let. According to Chandrakanthappa et al., (2001) Rasp bar type thresher was the best among different methods of threshing. A mini thresher consisting of a threshing mechanism along with winnowing capability was developed.

Material and Methods

Engineering Properties

The crop parameters influencing mechanical threshing of grains were identified and determined. The crop properties, relevant to the design of thresher components were identified as the length and thickness of panicle, weight of grains per panicle, size and shape, thousand grain weight, bulk density, true weight, porosity and angle of repose. The manners of measurement and characterization of these properties are discussed in the following sections. The most popular varieties among the farms of Tamil Nadu such as ASD18, ADT36 and IR20 were used throughout the investigation.

Length of Panicle

One paddy panicle was selected at random from the harvested heap and its length and thickness was measured with a scale after placing it on a horizontal platform in its natural rest position. This procedure was repeated for nine more panicles of paddy and the observations were recorded. Similarly, the procedure was repeated for ten panicles of other two varieties and all the observations were tabulated. The moisture content of the grain was determined by OSAW moisture meter.

Weight of Grains Per Panicle

One panicle of paddy was selected at random. The grains in the panicle was separated manually and weighed by means of an electronic balance having a sensitivity of 0.1g. The procedure was repeated for nine more panicles of paddy and ten panicles in each of other two varieties. The observations were tabulated. The moisture content of the grains was determined.

Size and Shape of Grain

The size and shape of the grain are important parameters in designing the cylinder concave assembly and sieves. The size and shape of three paddy varieties viz. ASD18, ADT36 and IR20 were measured by following the method detailed below (Subramanian 1977).

a. Size

The size and shape of the grain of selected varieties viz ASD18, ADT36 and IR20 were determined by Mitotoaya, Japan make vernier caliper having the accuracy of 0.02mm. Twenty seeds of ASD18 variety were selected in random. The dimensions in three mutually perpendicular directions were measured using vernier caliper for a seed. The dimensions were measured for the remaining nineteen seeds. The observations were recorded. The procedure was repeated for other two varieties. All the observations were tabulated. The moisture content of the grain was determined.

b. Shape

The paddy grains have an ellipsoid shape with three main dimensions, the length (longitudinal dimension), the breadth (dorsoventral dimension) and thickness (lateral dimension). Paddy grain having length per breadth ratio over 3.0 is known as slender paddy. Paddy grain having length per breadth ratio in between 2.0 and 3.0 is known as bold grain paddy or medium grain paddy. And Paddy grain having length/ breadth ratio less than 2.0 is known as round or short grain paddy. The size of three varieties of paddy grain, determined was used to classify the grains as narrated above.

Thousand-Grain Weight

The weight of thousand grains randomly selected from a heap of paddy crop was weighed in an electronic weighing balance having a sensitivity of 0.1g. The experiment was replicated ten times and the observations were recorded. The procedure was repeated for other two varieties and all the readings were recorded (Subramanian 1977). The moisture content of the grains was determined.

Bulk Density

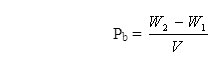

A 500 ml beaker was taken, cleaned and weighed in an electronic top pan balance. It was filled with freshly harvested and threshed grain up to rim level without compaction and weighed. The bulk density of grain was calculated as follows:

Where,

Pb = Bulk density of grain, g cm-3

W1 = Weight of empty beaker, g

W2 = Weight of beaker + grain, g

V = Volume of beaker, cm-3

The procedure was repeated ten times and the values were recorded. The experiment was repeated for other two varieties and the observations were tabulated. The moisture content of the grains was determined.

True Density

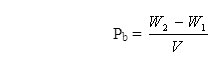

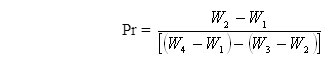

The true density of the grain was determined by water displacement method as described by Ouseph et al., (1968).

A 100ml beaker was taken. A sinker with wire mesh and handle was made. The empty beaker with the sinker inside was weighed. The beaker was half filled with the grain and weighed. Water was filled in the beaker till the grains were submerged. The grains were kept submerged in the water with the help of the sinker and again weighed. The water level in the beaker was also marked. Then the content of the beaker was poured out. The beaker was filled with water alone up to the previous water level mark and weighed. The real density was calculated using the formula:

Where,

Pr = True density, g cm-3

W1= Weight of empty beaker + sinker, g

W2= Weight of beaker + sinker + grain, g

W3= Weight of beaker + sinker + grain + water, g

W4= Weight of beaker + sinker + water, g

The experiment was replicated for ten times in each paddy varieties and the true density of the grains was calculated.

Angle of Repose

The angle of repose for the grain was determined by the method suggested by Waziri and Mettal (1983); the grain was heaped over a circular disc of 200 mm diameter by allowing them to fall from a height of 300 mm until maximum height was reached. The height was replicated ten times and readings were recorded. The angle of repose was determined by the following relationship:

q = tan-1 (h/r)

Where,

q = Angle of repose, degree

h = Height of the cone, mm

r = Radius of the disc, mm.

The same procedure was used for the other two varieties and all values were tabulated.

Development of Mini Paddy Thresher

A mini paddy thresher was developed with the following components based on the above study. Feed chute, Threshing cylinder, Concave, Outlet and grain collection assembly, Winnower, Main frame and Power unit. The overall dimension of the mini paddy thresher is 1500 × 900 × 1140 mm and width and diameter of the cylinder are 300 mm and 300 mm respectively. The weight of the mini paddy thresher is 102 kg with engine and thresher alone 83 kg.

Field Performance

The mini paddy thresher was field tested for threshing freshly harvested panicles of paddy, Figure 1. The thresher was set to run at fixed level of operational parameters by adjusting the concave clearance at 15 mm and cylinder peripheral speed 16.50 m s-1. The thresher was operated for a period of six hours with rasp bar threshing cylinder and the performance was evaluated following the test procedure described by IS: 11234: 1985.

|

Figure 1: Mini paddy thresher-performance study. Click here to View figure |

During each one hour run period, three sets of samples were collected at main grain outlet, chaff outlet and straw outlet for duration of 60 seconds at all the outlets. From the analysis of samples collected at different outlets, the performance of the thresher was assessed in terms of threshing efficiency, grain breakage and output capacity for the paddy crops tested.

Results and Discussion

Engineering Properties

The physical properties of ASD18, ADT36 and IR20 determined experimentally were the length and thickness of panicles weight of grains per panicles, size and shape of grains, thousand grain weight, bulk density, true density and angle of repose.

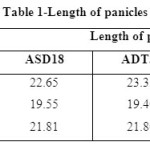

Length of Panicles

The length and panicles of panicles were measured and the statistical information is given in Table 1

|

Table 1: Length of panicles. Click here to View table |

From Table 1 it is inferred that the length of ASD18 varied from 19.55 to 22.65 cm. The mean length was 21.81 cm. For ADT36 the mean length was 21.80 mm, while the corresponding values for IR20 was 22.50 mm. The moisture content of the grain was in the range of 10 to 12 per cent (w.b) the results are in agreement with findings of Subramaniam et al., 1977.

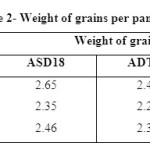

Weight of Grains Per Panicle

The weight of grains in each panicle was determined and the statistical information is furnished in Table 2.

|

Table 2: Weight of grains per panicle. Click here to View table |

From the Table 2, it is seen that the weight of grains per panicle for ASD18 varied from 2.35 to 2.65 g. The mean value of weight of grains per panicle was 2.46 g. while the corresponding values for ADT36 and IR20 were 2.34 and 2.90 g respectively.

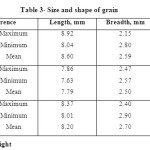

Size and Shape of Grains

The geometric of the three types of paddy varieties viz., ASD18 ADT36 IR20 taken for the study were measured.

|

Table 3: Size and shape of grain. Click here to View table |

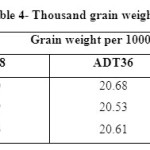

|

Table 4: Thousand grain weight. Click here to View table |

It was found that the average thousand-grain weight of ASD18, ADT36 and IR20 grain was, 21.86 g, 20.61 g and 18.97 g respectively as shown in Table 4 These results were similar to those reported by Subramanian et al., (1997).

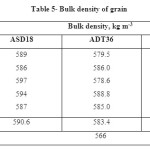

Bulk Density

|

Table 5: Bulk density of grain. Click here to View table |

From Table 5, it is seen that the bulk density of paddy variety ASD18 grain varied from 586 to 597 kg m-3 with an average of 590.6 kg m-3. The average bulk density for ADT36 and IR20 grains were, 583.4 and 524.2 kg m-3 respectively.

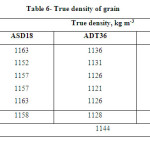

True Density

The true density of three varieties of grain is shown in Table 6. It is observed that for grain the mean value for true density varies from 1128 to 1158 kg m-3. The true density was higher for ASD18, (1158 kg m-3) and lower for ADT36, (1128 kg m-3).

|

Table 6: True density of grain. Click here to View table |

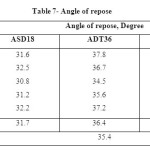

From the Table 7, it is observed that for three variety of grain the mean value of angle of repose varies from 31.7 degree to 38.0 degree. It is lower for ASD18, (31.7 degree) and higher for IR20, (38.0 degree.).

|

Table 7: Angle of repose. Click here to View table |

Field Performance

The field performance studies with the developed mini paddy thresher were carried out for threshing paddy. The mean values for test results in terms of threshing efficiency, grain damage and output capacity are 99 per cent, 1.55 per cent and 248 kg h-1 respectively.

Conclusions

The overall dimension of the mini paddy thresher is 1500 × 900 × 1140 mm and its output capacity, threshing efficiency and grain damage are 248 kg h-1, 99 per cent and 1.55 per cent, respectively. The analysis of variance revealed that all the above discussed properties were significantly influenced (p<0.01) by the paddy varieties.

References

- Chandrakanthappa.K, Batagurki, S. B. and Kammar. C. Mysore J. of Agric. Sci. 35(2): 28-132 (2001).

- Ouseph, C.C., Devassy. C.P and S.L.Thomas. A text book of practical physics- part. I. S.Viswanathan & Co., Madras, 46-48(1996).

- Sarvar, J.G and Khan A.U. AMA, Africa and lat. America, 18(2): 37-42(1987).

- Subramanian, V. Thenammai. P and Dakshinamurthy. A. J. Agrl. Engg. 14 (2): 81-84 (1997).

CrossRef - Waziri, A.N., and J.P. Mittal. AMA, Africa and Lat. America, 14(1): 59-62 (1983).