Introduction

Bananas rank fourth in the world as a dietary staple after rice, wheat and corn. It is a tropical herbaceous plant cultivated over 130 countries. The trunk of the banana tree is called the pseudostem which is of several leaf sheaths. Inside the central part of the pseudostem is the core which is edible. Banana plantations after harvesting of the fruits leave behind the pseudostem found abundant in banana growing areas as biomass. These pseudostems are normally burnt in the fields itself.

In many parts of India, the pith or the tender core of the banana pseudo-stem has been used as food after boiling and the addition of spices. Banana centre core is rich in fibre and aids in weight loss. It helps to relieve constipation. It is also found to be rich in potassium and vitamin B6. It helps to detoxify the body being a diuretic. It is used in the treatment of kidney stones (Chandrasekaran, 2012).

Banana centre core mainly comprises of 90 per cent moisture and hence cannot be kept for a long period of time. Banana centre core can be converted into flour which could be used to prepare bakery products, soup etc. The beneficial uses of plant flours in the pharmaceutical and food industry directly depend on their functional properties. Plant flours having high dietary fibre could be blended with wheat flour to increase the dietary fibre intake in the preparation of bakery products. Keeping in view of the wastage of banana pseudostem in plantations, the present study was aimed to convert the fresh banana centre core to flour which could have an extended shelf life and finds use in food applications. Banana centre core was dried by different drying methods for production of flour and their effect on the physical and functional qualities of the flour was found out.

Materials and Methods

Preparation of Banana Centre Core Flour

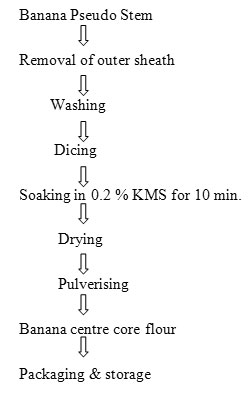

Banana pseudo stem of Nendran variety, procured from local market was cleaned to remove the outer sheath, washed and diced using a dicer. The dices were then soaked in a solution of 0.2% concentration of Potassium Meta bi sulphate (KMS) for ten minutes in order to control browning. They were then subjected to drying under sun, solar and cabinet (50, 60 & 70°C) from 90 % (w.b) initial moisture content to final moisture content of 5 % (w.b). The dried samples were powdered in a laboratory pulveriser (Wiley mill) to a fineness that 90 percent of the powder passed through 400 micron sieve. Flow chart for the production of flour from banana centre core is as follows:

Physical and Functional Properties of Banana Centre Core Flour

Colour

Colour was measured using Colour Flex Meter (Hunter model). Color was calibrated by fixing the defined colors like white and black tiles on the color flex meter. Calibration is performed through necessary changes in the sample. Measurement of color was done as per the above principle by determining ‘L’, ‘a’ and ‘b’ values.

pH

pH is a measure of the active acidity, which influences the flavour or palatability of a product and affects the processing requirements. The pH value was determined by using a digital pH meter (Systronics µpH system 361, Ahmedabad, India) and it was standardized with distilled water of pH 7.0. The pH of banana center core flour from different drying was estimated.

Total Soluble Solids

The banana center core was flour was estimated for its Total Soluble Solids using a hand refractometer (Maske: Erma, Japan) in the range 0-30. TSS was expressed as °Brix (Ranganna, 1995).

Optical Density

The extracts from the dried banana center core samples were kept in a centrifuge rotated at 4000 rpm for a period of 15 min. time. To the 20 ml of the resultant samples, 30 ml of 60% alcohol was added, mixed well and filtered. The absorbance of the filtrate at 440 nm using 60% alcohol as a blank was recorded and expressed as optical density (OD) (Srivastava & Kumar, 1998).

Water Holding Capacity

The functional properties viz., water holding capacity and oil absorption capacity were determined based on standard procedures. For estimating the Water holding capacity the procedure mentioned by Gould et al., (1989) was adopted with little modification. One gram of the flour sample (dried) was weighed into a centrifugal tube, made up with 10 mL distilled water. This was kept in a bench top centrifuge (Kubota 5100 Bench Top Centrifuge, Fujioka, Japan) and rotated at 3500 rpm for 15 min. The supernatant was removed and the hydrated sample was weighed. WAC was found from the following formula.

Water Holding Capacity = w1-w2 / 100 * Weight of sample taken

Where, w1= initial weight of sample before centrifugation

w2= weight of the sample after centrifugation

Oil Absorption Capacity

About two gram of the banana centre core flour was weighed, put inside a centrifugal tube, to which 20 mL of oil (refined cooking oil) was added and mixed. This was followed by centrifuging in a laboratory centrifuge at 1000 rpm for half an hour. The precipitate was removed and the supernatant weight was found by a measuring cylinder.

Oil Absorption Capacity = w1-w2 / 100 * Weight of sample taken

Where, w1= weight taken initially (before centrifugation)

w2 = weight taken after centrifugation

Bulk Density

The bulk density of banana centre core flour was measured by measuring its volume in a graduated cylinder. About two grams of the processed flour samples was measured into calibrated measuring cylinder. The bottom of the cylinder was tapped repeatedly on a pad placed on a laboratory beach. Tapping was done until there was no further diminution (reduction) in the volume occupied by the sample. The bulk density was determined by the following formula.

Where W = weight of samples in gram

V = volume (cm3)

Bulk Desity = weight of the sample(untapped) / volume of the sample(tapped)

Statistical Analysis

The experimental data were replicated thrice and statistically analysed using the statistical software AGRES to find out the significance between means.

Results and Discussion

Physical and Functional Properties of Banana Centre Core Flour

Color

Color measurement is an important quality parameter used to indicate the acceptability of a commodity. The color values namely, L*, a* and b* were significantly higher (P<0.05) in banana center core flour (Table 1). The ‘L’ value indicates the difference between lightness and darkness, where a (0-50) represents darkness and (51-100) represents lightness. It was observed from the table that the L value was highest in the tray dried sample at 50° C and the least value was noted during solar drying. The values were found to be significant.

Table 1: Effect of Drying on Color of Banana Centre Core Flour.

|

Drying Treatments |

“L” |

“a” |

“b” |

|

Sun dried |

68.75 |

4.25 |

14.08 |

|

Solar dried |

65.42 |

2.91 |

11.11 |

|

Tray dried 50° C |

77.21 |

0.85 |

15.28 |

|

Tray dried 60° C |

76.81 |

1.76 |

15.46 |

|

Tray dried 70° C |

74.91 |

0.34 |

13.33 |

|

SED |

0.0793 |

– |

– |

|

CD(.01)% |

0.2514 |

– |

– |

|

CD(.05)% |

0.1768 |

– |

– |

|

CV% |

0.13 |

– |

– |

pH, TSS and OD of Banana Centre Core Flour

From the table 2, the pH value has been near neutral. The drying methods had no effect on the maximum and minimum solubility’s pH the one with the highest pH value is 60°C dice and the lowest pH value is for Sun dried dice slightly acidic. The total soluble solids (TSS) ranged to a maximum of 1.2° brix, for 70° C dice. The least value was noted for solar dried dice. Banana centre core is susceptible to browning when exposed to air and is to be pretreated to arrest browning before dehydration. The absorbance value measured in terms of optical density to find the effect of drying on browning revealed that the sun dried samples had higher value whereas OD was least for the sample dried at 50° C. There were no much differences among the treatments as per statistical analysis on browning. This may be due to the effect of pretreatment with Potassium Meta bisulphate prior to drying to control discolouration. This was in agreement with the findings of Reihaneh & Mehedi (2010) for dried tomato.

Table 2: Effect of Drying on pH, TSS and OD of Banana Centre Core Flour.

|

Drying Treatments |

pH |

TSS, Brix |

OD |

|

Sun dried |

6.55 |

1 |

0.07 |

|

Solar dried |

7.08 |

0.8 |

0.05 |

|

Tray dried 50° C |

7.23 |

0.9 |

0.01 |

|

Tray dried 60° C |

7.27 |

1.1 |

0.03 |

|

Tray dried 70° C |

6.96 |

1.2 |

0.04 |

|

SED |

0.1114 |

0.0119 |

0.0037 |

|

CD(.01)% |

0.3531 |

0.0377 |

0.0116 |

|

CD(.05)% |

0.2482 |

0.0265 |

0.0081 |

|

CV% |

1.94 |

1.45 |

13.15 |

Table 3: Functional Properties of Banana Centre Core Flour at Different Drying Conditions.

|

Drying Treatments |

WHC (g/g) |

OAC (ml/g) |

BD (g/cm3 ) |

|

Sun dried |

11.88 |

0.27 |

0.238 |

|

Solar dried |

9.95 |

0.18 |

0.297 |

|

Tray dried 50° C |

8.84 |

0.26 |

0.327 |

|

Tray dried 60° C |

5.57 |

0.23 |

0.432 |

|

Tray dried 70° C |

4.87 |

0.28 |

0.519 |

|

SED |

0.0713 |

0.0056 |

0.0099 |

|

CD(.01)% |

0.2259 |

0.0177 |

0.0314 |

|

CD(.05)% |

0.1588 |

0.0125 |

0.0221 |

|

CV% |

1.06 |

2.84 |

4.00 |

Functional Properties of Banana Centre Core Flour

From the table 3, it could be seen that the sun dried dice has the highest water holding capacity and the 70° C sample with the least. Similar results have been noted for sun dried tomato. The water holding capacity of sun-dried samples was significantly higher than the water holding capacity of freeze-dried samples reported by Aletor O & Abiodun A R (2013) for leafy vegetables.

In the case of the oil absorption capacity, the highest value was noted for the sample dried at 70°C which is suitable for making bakery products. The lowest OAC was observed for the solar dried sample. Bulk density of the flour was more at 70° C dried samples. Bulk densities of the dehydrated powder were found to have increasing trend with increase in temperature of dehydration. Higher values of bulk density provide packing advantage (Muhammad et al., 2011).

Conclusion

The study aimed to produce flour from banana centre core which is normally considered a waste material in banana plantations. The influence of different drying methods on the quality of the banana centre core flour in terms of its physical and functional properties revealed that the flour prepared from banana centre core sample dried in a tray dryer at 70°C resulted in better quality product.

References

- Aletor. O. and Abiodun. A. R. (2013) “Assessing the Effects of Drying on the Functional Properties and Protein Solubility of some Edible Tropical Leafy Vegetables”, Research Journal of Chemical Sciences, 3(2):20-26.

- Chandrasekaran, S.V., Fibre of Health. THE HINDU dated 21.10.2012. Chennai edition

- Gould, J. M., Jasberg, B. K., & Cote, G. L. (1989). Structure-function relationships of alkaline-peroxide treated lignocellulose from wheat straw. Cereal Chemistry,66, 213–217

- Muhammad Aslam Shad, Haq Nawaz, Mazhar Hussain & Beena Yousuf (2011). Proximate composition and functional properties of rhizomes of lotus (nelumbo nucifera) from Punjab, Pakistan. Pak. J. Bot., 43(2): 895-904

- Ranganna S, (1986). Handbook of Analysis and Quality Control for Fruit and Vegetable Products; 2nd ed. Pp.589, Tata Mc Graw Hill Publishing Company Ltd., New Delhi, India

- Reihaneh Ahmadzadeh Ghavidel, Mehdi Ghiafeh Davoodi (2010). Studies on Physiochemical Properties of Tomato Powder as Affected by Different Dehydration Methods and Pretreatments. World Academy of Science, Engineering and Technology, 45:9-21

- Srivastava, R P., Kumar, S V. (1998) Fruit and Vegetable Preservation Principles and Practices Chaman Studio.