Introduction

The use of pesticide was widely studied due to the economic and environmental costs. More specialized methods were found for pesticide and plant protection products (PPP). Initially, distribution of agrochemicals was shared flawlessly on the gardens, due to that dose of each unit ground area was expressed as a dose rate. For many years, many researchers were analyzed and developed dose models for orchards, groves and vineyards.1,2,3 The purpose of pesticides needs to be technically effective. It includes more than the specific application of the selected mass of spray mixture. Since the cost of chemicals and applications has increased, here need more efficiency in spraying has become necessary. Recent trends in air-assisted spray applications are based on the use of non-conventional sprayers to increase in treatment options and reduce pollution. Poor match was appeared between the conventional air blast sprayer and the plant geometry in losses of insecticide.4, 5, 6

Orchards were identified by a large number of trees in small farms using height, density and a variety of tree shapes. It was led to sprayer manufacturers endorsing the design and development of machines with direct declining of traditional air blast sprayers with easy adjustment to match the crop canopy. An approach to achieving this objective was fitting of adjustable vertical air outlets. The arrangement of these sprayers takes many different aspects, some of which have been studied and others dose not checked.7 The most calculated solutions for improving spray control and reducing drift losses by adjusting air outlet of the sprayer that matches with canopy of the crop.8,9 Taking this approach to the extreme development of air-assisted sprayers, in which shield rows and recycling systems have the full edge of target spray liquid.10, 11

The objectives of this assessment were find out the effect of pesticide application, effect of forward speed, effect of blower revolution and effect of various pressures on air-assisted sprayer fitted with adjustable air outlets in a typical orchard. The performance of the equipment was studied using different fan speeds, air outlets positions, airflow, velocity and direction of the air stream changed during the spraying.

Review of Literature

Effect of Pesticide Application

The proper time of application of pesticides was important for controlling pesticides and reducing the use of pesticides. The effective pesticide application was based on application time, equipment selection, spray formulation and calibration. They gave an opinion that the quality of the application was important for the effectiveness of the application.12 The use of pesticides and other pest control products was a complex mechanical process, resulting in a complex biological response. Biologically active materials do not just use mechanical systems, but they also make attempts to protect non-targets such as complex ecological areas, human and animal territory, labors and natural beings. Developed sprayers, optimized devices and analytical methods were developed for large-scale irrigation and for special crops in the United States to detect drift and droplet size measurements and on-board electronic sensing and control systems.13

|

Figure 1: Conventional Air Blast Sprayer Click here to View Figure |

|

Figure 2: Tower Sprayer Click here to View Figure |

|

Figure 3: Tunnel Sprayer Click here to View Figure |

Ultra-Sonic sensors were used to measure map size of the tree canopy. It was useful to organize site-specific management practices and to estimate crop yield within the grove. Manually calculated parameters and output from ultra-sonic sprayer parameters were compared. Canopy foliage density was showed significant effect on the ultra-sonic measurement of tree canopy. The volume variance was higher in menial than the condensed trees. Ultra-Sonic sensors proverb a significant differences between the volumes of both sides of the tree.14 The residual effect of pesticides and natural toxicants in food cause increase the risk of cancer and sickness in the short time. Mostly, farmers or other agricultural laborers apply these chemicals to crops and its risky when exposed skin and eyes or through ingestion via the mouth and nose absorb chemicals at potentially toxic levels. After the time of application, contact of human body with chemical residues during other agricultural tasks like weeding, thinning and harvesting can also be problematic. Limiting exposure was achieved by wearing protective equipment and other strategies to keep the chemicals away from the body.15

Effect of forward speed on air assisted sprayer

A study was conducted to determine the spray deposition pattern for the aero blast sprayer, which was to apply chemicals in the vineyards on the canopy of Semilon Grapevine.16 The application run at 12 bar pressure and three operating speed 2.1, 4.9 and 7.7 km/hr. Spray deposition was measured at a various distance, which 1.5, 3, 6 and 9 meters on the point. Tracer material was applied as tartrazine. Most extreme deposition was accomplished 66.1 mg/cm2 at sprayer speed of 2.1 km/hr and least deposition was accomplished 37.1 mg/cm2 at operating speed of 7.7 km/hr. They discovered that sprayer motion had huge impact on spray deposit distribution and increased drift in the sprayer speed.

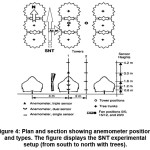

Commercial air assisted sprayer in asparagus crop with the operating speed 0.83 and 1.69 m/s. The air-assisted sprayer got a uniform deposition which was directed with four noses in each direction with a 6.1 m3/s air flow speed and a operating speed of 1.69 m/s in the horizontal direction.17 It was studied the effects of operating speed, nozzle size and air assistance deposition in laboratory experiments which simulated effect of deposition on vertical and horizontal targets. Small targets were placed in the swath of a Hardi Twin air-assisted crop sprayer and spraying inside with various conventional hydraulic nozzles with and without air assistance and at differing operating speeds. They concluded that with conventional spraying, deposition was improved by high operating speed on vertical targets with small droplet-size and also, deposition on horizontal targets was relatively unaffected by the configuration used. Air assistance has generally changed this behavior in a certain way by reducing the flexibility. The general trend was observed that the benefits of using air assisted sprying were higher with less operating speed.18 Computational fluid dynamics (CFD) was analyzed about air velocity distribution of an air-assisted sprayer and experiments were analyzed. The velocity size and prediction of the CFD model predicts that operating speed 0, 6 and 10 km/hr was presented for dynamic sprayer. The fan speed of 1360 rpm for distribution of velocity magnitude was 15-30 m/s and 1836 rpm for distribution of velocity magnitude was 20-40 m/s. The wind speed pattern from fan outlet leads to direction (between 0 and 37º vertical angle). The intensity and diversity of air velocity decreased dramatically by the tractor operating speed and however, there was an increase in the air speed in the jet’s highlands. Better agreements were found between the size and simulation of momentary velocity profiles as well as the maximum jet velocity distribution at different distances from the jet outlet.19 Into an apple tree canopy, air jet penetration of a sprayer was also measured. An air-assisted sprayer, with two verticals and a crossflow fan unit, offers air jets (without spraying the fluid) ahead of the tree. Replications included three fan locations (fans vertical [0/0], top fan inclined 20 [20/0], and top fan inclined 15 with bottom fan inclined 12 [15/12]), three operating speeds (4.8, 6.4, and 8 km/hr), two fan speeds (18 and 24.5 r/s), and three canopy conditions (south to north [SNT], north to south [NST], and north to south without a tree [NSO]. Air velocities show great and significant influence by fan speed. Operating speed produced little difference among treatments when maximum air velocity was considered. When there was a comprehension of integrated velocity, there were more differences. For conditions in canopy, more prominent speeds were estimated for the treatments without canopy and velocities for the south to north treatment were almost as incredible.20 In tree canopy, air velocities at different points to calculate the interactive effects of air flow rate, outlet of air velocity, sprayer operating speed and canopy resistance on jet velocity distribution was determined and noticed that the deflecting, spreading and absorbing the jet energy reduced the air velocity in the jet. The air velocity jet of 10-15% less produced at 6.4 km/hr operating speed than traveled at 3.2 km/hr operating speed. At higher operating speeds, air jets were more deflected and resulted less distribution of uniform spray.21

|

Figure 4: Plan and section showing anemometer positions and types. The figure displays the SNT experimental setup (from south to north with trees). Click here to View Figure |

|

Figure 5: RÉCUPAIR sprayer for orchard – spray recovery sprayer (SRS) Click here to View Figure |

Effect of blower revolution in air assisted sprayer

In some studies used air carrier unit with flat and hollow cone nozzles for single row foliar application. The nozzle units in the air were arranged between the columns between the angled 0 to 30º. The centrifugal fan was sent air to the nozzle through by flexible tubing. Three blower speeds 900, 1200 and 1500 rpm were used to vary velocity and airflow. For each hollow cone nozzle at 1500 rpm, air flow was 2.0 m3/min at 968 m/min and for each flat nozzle; air flow was 1.3 m3/min at 2031 m/min. For corn, the spray deposition on the entire plant was 100% by improved air carrier method and for soybean was 234%. For corn, deposition on upper-plant, bottom leaf surface increased by 900 and 400% for soybean plants.22 In another studies exhibit of two vertical adjustable air outlets in sprayers for vines and fan speeds at 1400, 2000, and 2500 rpm to check the effect of air outlets and the air-jet angles direction. Before the field trials, working evaluation of sprayer were analyzed by laboratory measurements. In the vineyard, the sampling method was based on the framework and the method of splitting nylon threads divided the canopy into the elementary volumetric zone. Input and output of spray flux in the canopy, ground losses and air velocity were measured. Spray coverage on leaves at different heights and depths on the leaves has also been calculated. In all the tests, air outlets were adjusted for the spray application to determined appropriate height by the development of the canopy. The 120º backward angle of the outlet side detectors shows the great result at the low and medium fan speeds. The direction of air flow was more clearly visible than the fan speed. The reduction of spray has doubled by the speed of the fan, and repeatedly this damage was not limited to the treatment sector, but it was drifted outside. The degree of spray coverage and the high degree of uniformity were very impressive.23 The rotary atomizer for aero blast sprayer at 1250, 1500, 1750 and 2000 rpm blower speeds and 850 ml/min discharge rates at around 3 kg/cm2 operating pressure at 6, 9, 12 and 15 m distance from outlet. It displays better spray on upper surface of leaves with large droplets and high-density leaves compared to the lower surface of the plant against the plant canopy and reverse phenomenon on the backside of plant.24

Effect of pressure in air assisted sprayer

In one study observed that, no definite pattern was found for the uniformity of spray distribution for all the nozzles at any angular setting and pressure. The discharge rate, swath width and working width increased with the increase in pressure for all the nozzles. The nozzle spacing for uniform distribution by the hollow cone, solid cone, adjustable and fan type nozzles were found to be 48, 42, 42 and 30 cm, respectively at operating pressure of 3.0 kg/cm².25 The characteristics of triple action, bi-action and hollow cone nozzles at operating pressures of 2.5, 3.0, 3.5 and 4.0 kg/cm2 were studied and recorded that the better spray distribution with triple action and bi-action nozzles as compared to hollow cone nozzle for all the four pressures. The bi-action nozzle gave best results at the pressure of 3.5 kg/cm2 with least coefficient of variation.26 A study carried out the evaluation of air carrier sprayer for orange orchards. The sprayer was operated at 5, 10 and 15 bar pressures and 2, 3 and 4 km/h travel speeds. They found that the tractor operating speed of 2 km/h and pressure 15 bars was better for the effective spraying.27 The efficacy and effectiveness of applied chemicals were affected by spray nozzle and its tips. It was the most neglected ingredient in today’s farming. Hollow cone nozzles having different orifice tips than plastic, brass and stainless steel nozzles, which were evaluated at 1.0, 3.0 and 5.0 kg/cm2 nozzle pressures to assess their performance in terms of increase in discharge rate and wear of orifice tip diameter. The result shows that plastic tip material could work within the permissible limit of 15% increase in discharge rate for about 90, 35 and 10 hr of use at operating pressure of 1.0, 3.0 and 5.0 kg/cm2, respectively. Similarly, brass tip material worked about 50, 30 and 7.5 hr and stainless steel for 90, 50 and 17.5 hr, respectively at operating pressure of 1.0, 3.0 and 5.0 kg/cm2. When compared with plastic and stainless-steel tip nozzle, the increases the average orifice diameter in all cases of brass tips nozzle increases.28

Summery of Review

Cost of pesticide is very high; preciseness in spraying application is also necessary to reduce wastage and minimize residual effects of pesticides. Pesticides are hazardous for human health condition, which directly affected by open skin like eye, nose, hand and legs. Skin should be protected by good quality body protective wares. The operating speed during spraying was having significant effect on spray droplets deposition and distribution by conspicuously greater with the lower operating speeds. In air assisted sprayer, the effect of blower speed was found significant on air velocity and efficiency of the sprayer. Performance of the sprayer was found better with increase in operating pressure (1 to 15 kg/cm2).

Acknowledgements

The authors are grateful to the necessary support given by Junagadh Agricultural University.

Funding

The author(s) received no financial support for the research, authorship, and/or publication of this article.

Conflict of Interest

The authors do not have any conflict of interest.

References

- Viret, O. and Höhn, H. Application de la dose selon la méthode du TRV. Revue suisse de Vitic. Arboric. Hortic. 2008; 40:50-51.

- Gil, E. and Escolà, A. Design of a decision support method to determine volume rate for vineyard spraying. Appl. Eng. Agric.2009; 25:145–151, 2009.

CrossRef - Planas, S., Rosell, J.R., Gil, E., Val, L., Escolà, A. and Solanelles, F. Optimizing pesticide spray application in tree crops. In: 2006 ASABE Annual International Meeting. 2006. Portland, USA.

- Cross, J. V. Patternation of spray mass flux from axial fan airblast sprayers in the orchard. BCPC Monograph, Air assisted Spraying in Crop Protection. 1991. 46:15-22.

- Giles, D. K., Delwiche, M. J. and Dodd, R. B. Spatial distribution of spray deposition from an air-carrier sprayer. Transaction of the ASAE. 1989. 32 (3): 807-811.

CrossRef - Wiedenhoff, H. Optimisation of spraying methods for fruit trees with reduced use of chemical. British Crop Protection Council Monograph. 1991. 46: 219-223.

- Pergher. G. and Gubiani, R. Analisi della distribuzione di antiparassitari su vigneto di una irroratrice a deflettori orientabili [Deposit analysis in vineyard from an air-assisted sprayer “tted with adjustable air outlets]. Proceedings of Giornate Fitopatologiche, a Symposium on Pesticide Application. 1996. Numana, Italy, 1: 447-454.

- Ade, G. and Pezzi, F. Valutazione di un’irroratrice per frutteto con convogliatore di flusso [Evaluation of a sprayer fitted with adjustable air outlets]. L’informatore Agrario. 1997. 19: 75-79.

- Baecker, G. Recent developments in recycling techniques for application in tree and bush crops. Proceedings of an International Symposium on Pesticides Application, Organized by the British Crop Protection Council, Strasbourg. 1993. 1: 331- 340.

- Balsari, P. and Tamagnone, M. Prime valutazioni di una irroratrice a tunnel impiegata in viticoltura [First evaluation of a tunnel sprayer in vineyard]. Proceedings of Giornate Fitopatologiche, a Symposium on pesticide Application. 1996. Numana, Italy, 1: 439-446.

- Baraldi, G., Bovolenta, S., Pezzi, F. and Rondelli, V. Air-assisted tunnel sprayers for orchard and vineyard: first results. In Proceedings, Symposium international sur les techniques d’application des produits phytosanitaires, Strasbourg, France. 1993. 1:

265-272. - Derksen, R. C. and Breth, D. I. Orchard air-carrier sprayer application accuracy and spray coverage evaluations. Applied Engineering in Agriculture. 1994. 10(4): 463-470.

CrossRef - Giles, D. K. Techniques and incentives in California for reducing pesticide inputs to mitigate water and air pollution risks in horticultural crops. AAB. 2008. 84: 395–402.

- Zaman, Q. U. and Salyani, M. Effects of foliage density and ground speed on ultrasonic measurement of citrus tree volume. Applied Engineering in Agriculture. 2004. 20(2): 173.

CrossRef - Culliney, T., Pimentel, D. and Pimentel, M. Pesticides and natural toxicants in foods. Agriculture, Ecosystems and Environment. 1992. 41: 126-150.

CrossRef - Celen, I. H., Arin, S. and Durgut, M. R. The effect of the air blast sprayer speed on the chemical distribution in vineyard. Pakistan Journal of Biological Sciences. 2008. 11(11): 1472-1476.

CrossRef - Pergher, G., Zucchiatti, N. and Gubiani, R. Influence of spray application parameters on deposition in an Asparagus crop. Journal of agricultural engineering research. 1999. 73(1): 19-28.

CrossRef - Nordbo, E. Effects of nozzle size, travel speed and air assistance on deposition on artificial vertical and horizontal targets in laboratory experiments. Crop Protection. 1992. 11(3): 272-278,

CrossRef - Delele, M. A., De Moor, A., Sonck, B., Ramon, H., Nicolaï, B. M. and Verboven, P. Modelling and validation of the air flow generated by a cross flow air sprayer as affected by travel speed and fan speed. Biosystems Engineering. 2005. 92(2):165-174.

CrossRef - Svensson, S. A., Brazee, R. D., Fox, R. D. and Williams, K. A. Air jet velocities in and beyond apple trees from a two–fan cross–flow sprayer. Transactions of the ASAE. 2003. 46(3): 611.

CrossRef - Reichard, D. L., Retzer, H. J., Liljedahl, L. A. and Hall, F. R. Spray droplet size distributions delivered by orchard sprayers. Transactions of the ASABE. 1977. 20: 232-237.

CrossRef - Watson, D. G. and Wolff, R. L. Air carrier technique for row crop spraying applications. Transactions of the ASAE. 1985. 28(5): 1445-1448.

CrossRef - Pezzi, F. and Rondelli, V. The performance of an air-assisted sprayer operating in vines. Journal of Agricultural Engineering Research. 2000. 76(4): 331-340.

CrossRef - Deogirikar, A. A. Performance evaluation of rotary nozzles for air assisted sprayers for cotton crop. EOS. 2010. 3: 4.

- Singh, S., Manes, G. S. and Sandher, N. S. Studies on spray pattern of different nozzles. J. Res. Punjab Agric. Univ. 2002. 39(3): 399-407.

- Singh, S. K., Singh, S., Sharda, V. and Singh, N. Performance of different nozzles for tractor mounted sprayers. J. Res. Punjab Agric. Univ. 2006. 43(1): 44-49.

- Tekale, D. D., Kawade, S. C. and Sawant, B. P. Performance evaluation of air carrier sprayer for orange orchard. Karnataka J. Agri. Sci. 2007. 20(2): 330-32.

- Sukumaran, S., Manes, G. S., Singh, S. K., Singh, A. and Dixit, A. Effect of Spraying Pressure and Usage on Discharge Rate and Wear of Hollow Cone Nozzle having different Nozzle Tip Material. Journal of Agricultural Engineering. 2013. 50(1): 1-8.