Introduction

Tobacco also called “Golden Leaf” is one of the important commercial crops grown in India and being so, it is vital in the Indian economy. It provides direct and indirect employment to 38 million people, around 70 per cent of whom are in the agricultural sector. The combined tax revenue collected annually from tobacco products was 21,463 crores and 6058.13 crores in terms of foreign exchange to the National Exchequer during 2015-16. India has a prominent place in the production of tobacco in the world. India stands second in production of tobacco and third in the export of tobacco in the world. Indian tobacco is exported to over 119 countries across the globe.8 According to the International Encyclopaedia of Social Sciences, tobacco was first used by the Americans. Tobacco was introduced in India by Portuguese in the seventeenth century. The Kaira district of Gujarat State was probably the first to grow tobacco and subsequently, its cultivation extended to other parts of the country.7

Tobacco is an agricultural product processed from the leave of the plant. Botanically, the tobacco plant belongs to the family Solanaceae and genus Nicotiana. The genus Nicotiana has more than 60 species of which two are important and commercially cultivated for the production of tobacco viz., N. tabacum and N. rustica. About 5 to 6 per cent of the total area under tobacco is accounted for Nicotiana rustica varieties, whereas, Nicotiana tabacum accounts for more than 85 per cent of the total area under tobacco. The varieties of tabaccum, which are called desi type, have tall plants with long, broad leaves and usually pink flowers.

World Scenario

Tobacco is cultivated in both tropical and sub-tropical climatic parts of the world. About 124 countries produce tobacco on almost 4.3 M ha (million hectares) of agricultural land, an area larger than Switzerland. China stands first in production followed by India, Brazil, United States, Indonesia, Malawi, Turkey, Argentina, and Zimbabwe.7 During 2015-16, production of 7.5 M T (million tons) of tobacco leaves with a productivity of 2087 kg/ha.8

The Asian countries had a major share in area and production of the tobacco constituting more than 55 per cent of the world output of tobacco leaves, the major countries being China (42.33 % of the world production), India (11.4 %), Indonesia (3.4 %) etc. African countries like Brazil contributed 10.82 per cent of the total production, while, Malawi 2.02 per cent and Zimbabwe 1.53 per cent. The USA contributed 4.61 per cent to the total world production.3

Indian Scenario

Tobacco crop is grown in an area of 0.45 M ha (0.27 % of the net cultivated area) producing ~ 650 M kg of tobacco leaf and a productivity of 1693.9 kg/ha. India is the second largest producer after China and the third largest exporter after Brazil and United States. Among the different tobacco types cultivated in India, bidi tobacco forms the biggest chunk (36 %) followed by Virginia tobacco (16 %), Natu tobacco (9.5 %) and Hookah tobacco (7.6 %). The production of flue-cured Virginia (FCV) tobacco is about 210 M kg from an area of 0.20 M ha while 450 M kg non-FCV tobacco is produced from an area of 0.25 M ha. In the global scenario, Indian tobacco accounts for 10 per cent of the area and 9 per cent of the total production2.

During 2015-16, India’s unmanufactured tobacco (FCV and non-FCV) exports accounted for about 86 per cent of total exports of tobacco and tobacco products in terms of quantity and 71 per cent in terms of value in rupees. Out of the total Indian unmanufactured tobacco exports, FCV tobacco exports constituted 72 per cent in terms of quantity and 81per cent in terms of value. FCV tobacco exports were in the order of 1,51,670 Metric tons valued 3,495.81 crores against 1,49,700 Metric tons valued at 3,201.71 crores during the same period last year showing an increase of 1 per cent and 9 per cent in terms of quantity and value, respectively. The unit price realization from the export of tobacco is around 230.40/kg.

Although FCV tobacco production (209.77 M kg) constitutes only about 30 per cent of the total tobacco production of which 151.67 M kg were exported, is of considerable significance.1 It is mainly grown in the states of Andhra Pradesh and Karnataka. About 55 per cent of the FCV tobacco production in India comes from Andhra Pradesh. East Godavari, West Godavari, Krishna, Guntur, Prakasam and Nellore are the important districts growing FCV tobacco. About 44 per cent of the FCV tobacco is grown in the transitional belt of Karnataka comprising of Mysuru, Hassan and Shimoga districts.8

Methodology

Data and its Sources

Both primary and secondary data were used in the study. Primary data were collected by personally interviewing the sample farmers with the help of pre-tested schedule specifically designed for the purpose. Secondary data were collected from various published and un-published reports, Journals, Official record of government, Agricultural office, Tobacco Board and Central Tobacco Research Institute, Rajahmundry.

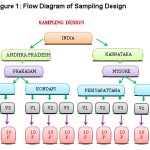

Sampling Design

Multistage random sampling procedure is followed; two states producing maximum production of FCV tobacco in the country were selected purposively. One district was selected purposively from each state where the production is maximum. Thereafter, two blocks were selected randomly from each selected district. In the next step, three villages were selected randomly from each block, wherein tobacco is being produced. From the selected villages a list of farmers cultivating tobacco was prepared and 10 farmers were selected randomly from each village. Thus, a total 120 farmers were selected for collection of primary data.

|

Figure 1: Flow Diagram of Sampling Design. Click here to View figure |

Table 2: Chart on sampling design.

|

State |

District |

Block |

Village |

No. of respondents |

|

Andhra Pradesh |

Prakasam |

Ongole |

Tangutur |

10 |

|

Shivapuram |

10 |

|||

|

T. Naidupalem |

10 |

|||

|

Kondapi |

Peridepi |

10 |

||

|

Anakarlapudi |

10 |

|||

|

Mupparajupalem |

10 |

|||

|

Karnataka |

Mysuru |

Periyapattana |

Kampalapura |

10 |

|

Bettadapura |

10 |

|||

|

Makod |

10 |

|||

|

Hunsur |

Kattemalavadi |

10 |

||

|

Thattekere |

10 |

|||

|

Uhigowdanahalli |

10 |

|||

|

Total |

02 |

04 |

12 |

120 |

Identification of Constraints in the Production of FCV Tobacco Garrett’s Ranking Technique

Garret’s ranking technique has been used to analyse the constraints in production of FCV tobacco. The sample farmers were asked to rank the given constraints in FCV tobacco production.5

Following constraints were put before the respondents to rank.

Inadequate and untimely rainfall

Non–adoption of improved method of nursery

Not aware of recommended package of practices

Scarcity of labour

Inadequate availability of finance

Attack of pest and diseases

High cost of firewood

Non-contact with extension agency

Ranks given by the farmers were converted to the per cent position by using the following formula, which was again converted to scores by referring to table given by Garrett and Woodworth.

Percent position = 100 (Rij – 0.5)/Nj …(1)

Where,

Rij = Rank given for ith constraint by jth respondent

Nj = Number of constraint ranked by jth respondent

Results

Constraints Faced by the FCV Tobacco Growers

The constraints faced by the farmers in FCV tobacco cultivation are discussed under this section. To study the various constraints associated with FCV tobacco cultivation, eight constraints were put before the sample farmers and asked to rank them according to their severity. The constraints faced by the farmers are analyzed by using Garrett’s ranking technique. The rank given by the farmers are converted into per cent position. Therefore, per cent position is converted into score and finally the scores are converted into the ranks by using the Garrett’s ranking table. Ranks of different constraints along with their scores have been presented in table 3.1.

Table 3.1 reveals that inadequate and untimely rainfall emerged as the top most constraint for the sample farmers with a mean score of 77.27 in Andhra Pradesh, whereas, in Karnataka the same constraint stood second with a mean score of 72.95 ranked first. Scarcity of labour and non-adoption of improved method of nursery became second and third constraint for the farmers in Andhra Pradesh, while in Karnataka they stood at second and sixth ranks, respectively. Inadequate availability of finance is the least severe constraint for Andhra Pradesh and Karnataka by indicating that bank, co-operatives and other financial institutions serving tobacco growers in a better way.

Table 3: Ranking of the constraints faced by the FCV tobacco growers.

|

Sl. No. |

Constraints |

State |

|

|

Andhra Pradesh |

Karnataka |

||

|

01 |

Inadequate and untimely rainfall |

I (77.25) |

II (72.95) |

|

02 |

Non–adoption of improved method of nursery |

III (59.51) |

VI (39.65) |

|

03 |

Not aware of recommended package of practices |

VI (37.46) |

V (43.95) |

|

04 |

Scarcity of labour |

II (70.1) |

I (73.15) |

|

05 |

Inadequate availability of finance |

VIII (23.65) |

VIII (27.61) |

|

06 |

Attack of pest and diseases |

V (46.31) |

IV (50.83) |

Discussion

Constraints Faced by the FCV Tobacco Growers

Results pertaining to constraints faced by the FCV tobacco growers presented in table 3.1 reveals that due to poor rainfall in study area of Andhra Pradesh, inadequate and untimely rainfall became the most severe constraint whereas, study area of Karnataka receives moderate rainfall as it comes under semi-transitional zone, so that the same constraint became second most. Majority of the sampled farmers from Karnataka expressed that main constraint in tobacco cultivation was the scarcity of labour which is due to high wages offered by industries in the urban area whereas, in Andhra Pradesh total manual operations were given on contract basis so that labour scarcity became less important. Non-adoption of an improved method of nursery, the high cost of firewood and attack of pests and diseases were other severe constraints in Andhra Pradesh whereas, the high cost of firewood, attack of pests and diseases and not aware of a package of practice were other severe constraints in Karnataka. In another studies were also observed similar kind of constraints.4,6

Summary

Untimely rainfall emerged as most severe constraint faced by the farmers in Andhra Pradesh, whereas, scarcity of labour has been most severe constraint for farmers in Karnataka.

Conclusion

Rainfall, scarcity of labour and high cost of firewood has been the major constraints faced by the FCV tobacco growers. Hence, farmers should be educated to adopt water conservation practices in their fields. High cost of firewood also emerged as a major constraint; the concerned agencies should take necessary steps to provide alternative fuel material other than wood. At the same time the concerned scientists must take up a research study to find out the alternative fuel at cheaper rates to reduce the cost of curing as well as to check the deforestation.

In the study area almost all the tobacco growers are found to be curing their tobacco green leaves with their traditional barn structures. This calls for establishment of mechanised processing unit to cure the FCV tobacco leaves for quality improvement. This will benefit farmers as well as enhance the trade competitiveness, besides, less requirement of human labour.

Acknowledgements

I deem it my privilege to have undertaken this investigation under the able, thoughtful, inspiring guidance and expert supervision of Dr. S. K. Srivastava, Associate Professor, Department of Agricultural Economics and Chairman of my Advisory Committee.

I offer my sincere thanks to Mr. Rajshekhar, Auction officer, Tobacco Auction Platform Hunsur-II, Hunsur, for providing me necessary information and facilities for this work.

I express my special thanks to Mr. Harish, K. A. field officer, Tobacco Auction Platform Tangutur, Ongole, AP, for providing me necessary information and also accommodation during my field work. Mr. Ashok, G. V.my friend who helped me for data collection in Andhra Pradesh.

Last but not least my sincere thanks to all beloved and respected sample farmers for their righteous information.

References

- Chandrakant B.K., Patil R.S., Prasad S. B. Production of Flue-cured Virginia tobacco in Karnataka: An econometric approach. Indian Journal of Agricultural Economics. 1980:28(2):135-137.

- CTRI- Rajahmundry. http://www.ctri.org. 2016.

- FAOSTAT, www.FAOSTAT.com.

- Jansirani R., Somasundaram S. And Ranganthan G. Prospects and problems of betelvine cultivation. Indian Journal of Extension Education. 2001:12(3): 3196-3200.

- Nagaraj C. V. Economic of Flue Cured Virginia tobacco production in Periyapatna taluk, Mysore district, Karnataka. M. Sc. (Agri) Thesis (Unpublished) U.A.S., Banglore. 1990.

- Radhakrishnan T., Mathaiya K., Ravichandran V. Constraints experienced by mango growers. Journal of Extension Education. 1999:10: 2520-2522.

- Rajesh T. a study on production and marketing of bidi tobacco crop in Belagaum district, Karnataka – An economic analysis. M. Sc. (Agri) Thesis (Unpublished) U.A.S., Banglore. 2011.

- Tobacco Board http://www.Tobacco Board.com accessed on 05 May. 2017.